-

Height-Adjustable Working Tables

-

Engine Powered

-

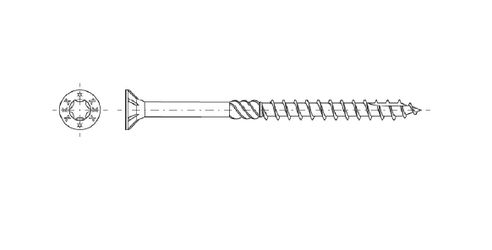

Construction Screws

-

Special Materials CRISCO

-

Accessories - Tool Materials

-

Blades

- Aluminium Cutting Blades

- Aluminium Cutting Blades (Special Tooth for Thin Profiles)

- Aluminium Cutting Blades (Special Tooth)

- Diamond Blades for General Cut

- Diamond Premium Blades

- Mild Steel Cutting Blades

- Multi-Material Cutting Blades

- Multi-Material Diamond Blades

- Saw Blades VIRUTEX

- Scorring Saw Blades

- Solid Surfaces Cutting Blades (Special Alloy & Tooth)

- Stainless Steel Cutting Blades

- Thin Steel Cutting Blades

- Wood Blades Fine Cut

- Wood Blades General Cut

- Wood Composite Cutting Blades (Hollow Tooth)

- Wood Composite Cutting Blades (Particleboard, MDF, OSB etc.)

- Wood Composite Cutting Blades for Machines (Special Tooth)

- Wood Cutting Blades (Solid Wood)

-

Blades

-

Glue Feeders

-

Wood Repair System

-

Pneumatic Tools

-

Power Tools

-

Battery Tools

-

Hand Tools

-

Fastening Materials

-

Upholstery Machines

-

Digital Measuring Tools

-

Clamping Systems

-

Sanding Systems

Box

- Quantity (in thousands): 100

Carton Box

- Quantity (in boxes): 12

Box

- Quantity (in thousands): 100

Carton Box

- Quantity (in boxes): 12

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 12

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 12

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 12

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 8

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 8

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 8

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 8

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 8

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Box

- Quantity (in thousands): 50

Carton Box

- Quantity (in boxes): 6

Request a Quote for: Wood Building Screws Ø8,0mm from 80 to 400mm

Applications

|

|

||||